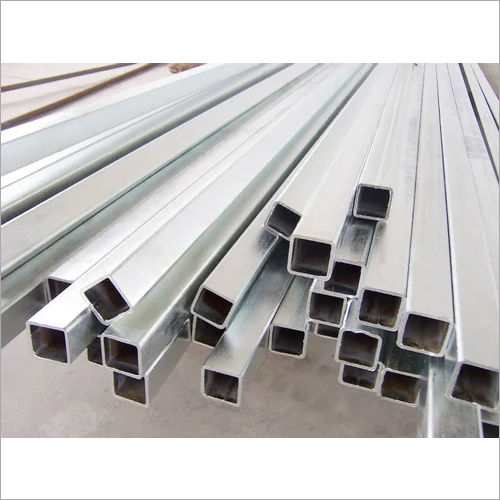

GI Square Pipe

GI Square Pipe Specification

- End Protector

- Metal Pipe Cap

- Type

- Galvanized

- Surface Finish

- Manual Polish

- Product Type

- Galvanized Steel Pipes

- Material

- Mild Steel

- Shape

- Round

- Surface Treatment

- Galvanized

- Color

- White

GI Square Pipe Trade Information

- Minimum Order Quantity

- 5 Tons

- Supply Ability

- 100000 Tons Per Month

- Delivery Time

- 2 Days

- Main Domestic Market

- All India

About GI Square Pipe

Construction, infrastructure, fabrication, and engineering are just a few of the many fields and uses for GI square pipes. They are favoured for their power, toughness, and resistance to corrosion and rust. They are useful for structural uses, such as framework, support columns, fences, and handrails, because to their square shape.

GI square pipes parameters can change, including their length, breadth, and wall thickness. Sizes as tiny as 1/2 inch and as large as 4 inches or more are considered common. These pipes are offered in a variety of gauges or thicknesses, which affects how much weight they can support.

Its crucial to adhere to the proper safety precautions and laws when dealing with GI square pipes. When handling these pipes, the proper protective gear, including gloves and eye protection, should be worn because they sometimes have sharp edges.

Although GI square pipes are frequently used, its important to keep in mind that other materials, such as stainless steel or aluminium square pipes, may also be available based on the particular requirements of a project or application.

Advanced Protection and Lasting Finish

The GI Square Pipe includes sturdy metal end protectors and benefits from a galvanized surface treatment, ensuring resistance to corrosion even under challenging environments. The manual polish offers a smooth exterior, while the classic white hue adds a refined touch. These features combine to deliver a pipe that not only performs well but also maintains its aesthetic appeal over time, making it suitable for high-visibility installations.

Versatility Across Industries

These galvanized mild steel pipes are widely used in construction, fabrication, and infrastructural projects throughout India. Their round end protectors minimize damage during handling and installation, extending the pipes operational life. The pipes are appropriate for both indoor and outdoor purposes due to their high durability and corrosion resistance, making them a preferred choice among professionals.

FAQs of GI Square Pipe:

Q: How is the end protector beneficial for the GI Square Pipe?

A: The end protector safeguards the pipes ends from damage and moisture, extending the pipes longevity and maintaining its structural integrity during transport, storage, and installation.Q: What process is used for the surface treatment of these pipes?

A: The pipes undergo galvanization, where a protective zinc coating is applied to the mild steel surface, followed by a manual polish to ensure a smooth finish and increased rust resistance.Q: Where can GI Square Pipes with End Protectors be used?

A: These pipes are suitable for diverse applications, including building infrastructure, industrial frames, fencing, and machinery thanks to their corrosion protection and robust design.Q: When should I choose galvanized mild steel pipes over regular steel pipes?

A: Galvanized pipes are preferable when you require enhanced corrosion resistance, particularly in outdoor or moisture-prone environments, providing greater durability compared to non-galvanized steel.Q: What is the main usage of the round metal pipe cap?

A: The round metal pipe cap prevents debris entry, reduces the risk of injury from exposed pipe ends, and offers a neat appearance, thus improving both safety and aesthetics.Q: How does manual polish affect the surface finish of the pipe?

A: Manual polishing provides a smoother, more uniform surface, enhancing the pipes appearance and reducing the chance of surface imperfections, which may otherwise lead to early corrosion.Q: What are the benefits of sourcing GI Square Pipes with end protectors from a supplier in India?

A: Indian suppliers offer competitive pricing, reliable supply chains, and quality assurance, ensuring you receive durable pipes tailored for local requirements and standards.

Price 58000 INR/ Ton

- Minimum Order Quantity

- 5 Tons

- Supply Ability

- 100000 Tons Per Month

- Delivery Time

- 2 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pipes Category

GI Pipe

Price 58000 INR / Ton

Minimum Order Quantity : 5 Tons

Material : Mild Steel

Shape : Round

Color : White

Product Type : Galvanized Steel Pipes

MS Pipe

Price 51 INR / Kilograms

Minimum Order Quantity : 5 Tons

Material : Mild Steel

Shape : Round

Color : Black

Product Type : Bushing

SS Pipe

Price 58000 INR / Ton

Minimum Order Quantity : 5 Tons

Material : Stainless Steel

Shape : Round

Color : White

Product Type : Bushing

MS Square Pipe

Price 51 INR / Kilograms

Minimum Order Quantity : 5 Tons

Material : Mild Steel

Shape : Square

Color : Black

Product Type : Bushing

GST : 19ALVPP1192L1Z7

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free