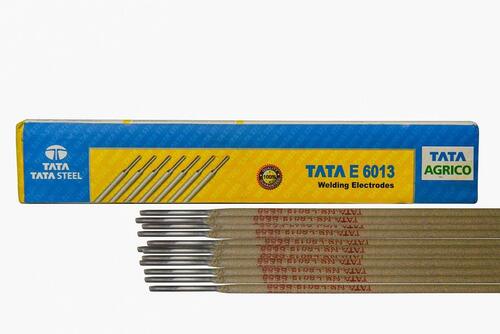

Welding Electrodes

Welding Electrodes Specification

- Usage

- Construction

- Material

- Mild Steel

- Size

- 3 mm

- Opening Pattern

- AC

- Product Type

- Welding Electrodes

- Color

- Grey

Welding Electrodes Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Welding Electrodes

Consumable electrodes, commonly referred to as welding rods or filler rods, are used in a variety of welding techniques to form a weld connection. They are often made of an electrically conductive metal alloy or a combination of metals that melt when welding to fuse the workpieces together.

The following are some essential welding electrode types:

- Stick electrodes, sometimes referred to as shielded metal arc welding (SMAW) electrodes, are frequently employed in manual arc welding. They are made up of a flux-coated metal core wire. The flux coating offers extra alloying components or fluxing agents, protects the weld pool from impurities, and stabilises the arc.

- Electrodes for Gas Metal Arc Welding (GMAW) and Flux-Cored Arc Welding (FCAW) are used in automatic and semi-automatic welding procedures, respectively. While FCAW electrodes have a hollow core filled with flux that provides the necessary shielding and additional alloying elements, GMAW electrodes are solid wires that need an external shielding gas for protection.

- Electrodes for Gas Tungsten Arc Welding (GTAW): TIG (Tungsten Inert Gas) welding uses GTAW electrodes, also referred to as tungsten electrodes. Tungsten or a tungsten alloy, which has a high melting point and superior electrical conductivity, is the material used to make them. The electrode in GTAW serves as a heat source and a steady arc rather than contributing to the weld pool.

- Solid or flux-cored wire is constantly fed into the weld junction to form the Submerged Arc Welding (SAW) electrodes. They are employed in a submerged arc welding procedure where the weld pool is shielded from air pollution and the arc is protected by a granular flux.

The welding procedure, base material, thickness, desired weld qualities, and ambient variables all play a role in choosing the best welding electrode. Different electrodes have unique properties that make them appropriate for particular purposes, such as tensile strength, corrosion resistance, and weld bead appearance.

To ensure optimal weld quality, performance, and safety, it is imperative to choose and use welding electrodes in accordance with the manufacturers guidelines and welding protocols.

Reliable Welding for Construction Projects

Our mild steel 3 mm electrodes are engineered to meet the rigorous demands of construction sites. They deliver stability under AC current, offering dependable arc performance during long welding sessions. Whether youre fabricating beams or reinforcing frames, these electrodes provide consistent bonds essential for durable structures.

Sourced from Trusted Suppliers in India

We connect you with reputable suppliers and traders from across India, ensuring product authenticity and a steady supply of quality welding electrodes. Our network helps construction professionals and businesses access industry-standard consumables for ongoing projects, minimizing downtime and maintaining high work standards.

FAQs of Welding Electrodes:

Q: How are these mild steel welding electrodes used in construction?

A: These electrodes are typically employed for joining mild steel components in construction, such as beams, columns, and reinforcements. They facilitate strong and reliable welds essential for structural integrity.Q: What are the advantages of using 3 mm electrodes with an AC opening pattern?

A: The 3 mm size provides a balance between penetration and control, while compatibility with AC welding machines offers flexibility on construction sites that often use standard AC power sources.Q: When should I choose grey, mild steel electrodes over other types?

A: Use these grey mild steel electrodes when you require strong welds on general construction steel parts. Their composition and coating suit basic fabrication and repair tasks common in building projects.Q: Where can I purchase these welding electrodes in India?

A: These electrodes are available through various suppliers and traders across India. We recommend sourcing them from recognized industrial distributors to ensure authenticity and consistent quality.Q: What is the process for welding with these electrodes?

A: Begin by preparing the steel surfaces, then set up your AC welding machine. Insert the 3 mm mild steel electrode and establish an arc, moving steadily along the joint to ensure uniform weld bead formation.Q: What are the benefits of using these electrodes in construction applications?

A: They offer strong adhesion, reliable performance on mild steel, and ease of use with standard AC weldersresulting in durable, high-quality welds that support structural safety and longevity.

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1000 Sets Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

GST : 19ALVPP1192L1Z7

Send Inquiry

Send Inquiry Send SMS

Send SMS